Deepwater Horizon – the offshore oil industry’s worst-case scenario

The explosion at the Deepwater Horizon mobile drilling rig on 20 April 2010 caused the largest accidental oil spill in the oil industry’s history, releasing around 700,000 tonnes of crude oil into the Gulf of Mexico. Only the Gulf War oil spill from Kuwait in 1990 released more oil into the marine environment. Eleven workers on Deepwater Horizon lost their lives and 16 others were seriously injured in the blowout. In its final report, published in December 2011, a US committee of experts concluded that a series of technical failures and flawed decisions led to the disaster. This precipitated a controversial debate about responsibility and ways of avoiding similar disasters in future.

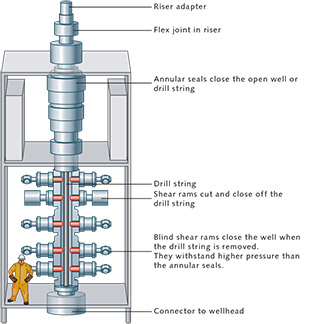

Deepwater Horizon was a semi-submersible mobile offshore drilling unit, designed to drill wells in new oil fields in ultradeep water. Drilling rigs of this type are operated by service companies which are contracted by oil companies to carry out drilling operations. To start with, drilling only penetrates a few metres into the sea floor. Sections of pipe, known as casing, are then placed in the drill hole. The casing has two functions: firstly, it provides structural integrity for the drill hole and prevents it from caving in immediately. And secondly, the casing head supports the blowout preventer (BOP), which is installed on top of the casing on the sea floor. The BOP is a structure around 10 metres high, fitted with shut-off valves to prevent any uncontrolled surge of oil and gas from the drill hole during or after drilling. The BOP surrounds the drill string like an over-sized cuff. As a further safety measure, the BOP is also fitted with devices known as shear rams: in the event of the valves failing, these act as twin jaws, cutting off the drill string and stopping the flow of oil from the drill hole or the BOP.

Once the service company has opened the well, its work is done. The drill string is removed and the BOP valves are closed, securing the drill hole. The rig then travels under its own power, or is towed, to the next well. The BOP remains closed until a production rig is installed on top of it. The valves on the BOP are not opened until the BOP is connected to the production rig with a pipe or hose, and extraction of the oil can begin.

fig. 1.34 > A blowout preventer is a tower-like structure which acts as a large plug. Fitted with shut-off valves and shear rams, its purpose is to seal off wells on the sea floor. The Deepwater Horizon disaster occurred partly because the BOP technology failed. © nach The Times Picayune

The Deepwater Horizon explosion occurred at the end of drilling operations during the process of sealing the well at a water depth of around 1500 metres, before oil production began. The critical moment came when the drilling fluid was being pumped out of the drill hole. This drilling fluid is pumped in during drilling in order to transport the crushed rock out of the hole. It also stabilizes the drill hole; otherwise, the high pressure in the reservoir would normally cause the oil – and the gas that it often contains – to burst through the walls of the drill hole and surge out of the hole. The drilling fluid produces the necessary counter pressure. Once the drilling has finished, the drill string and the drill bit are removed from the hole and the drilling fluid is displaced with sea water. However, water is much lighter than drilling fluid and therefore exerts less downward pressure in the well to balance the flow of gas and oil. The well is therefore additionally sealed with a cement plug far down in the rock. While this operation is being performed, the specialist drilling contractors on deck perform pressure tests to check whether the cement seal at depth is tight. These cementing operations are also carried out by specialist service providers. In other words, on an oil rig – as on any construction site – there are always operatives from several different companies, whose work must be precisely coordinated.

In the case of Deepwater Horizon, the tests indicated that there were pressure problems and that the cementing was inadequate. However, the engineers on board made a fatal error: they misinterpreted the pressure test results, assuming that there were distortions in the readings, and continued to displace the drilling fluid with sea water. Then the accident occurred: high pressure forced the gas out of the reservoir into the wellbore. The cementing failed, so the gas surged through the drill string to the rig, where it accumulated on deck and was ignited, probably by a spark from an engine room. Under normal circumstances, the blowout preventer, which had already been installed on the sea floor, would have prevented this gas surge. However, the shear rams failed as well. As a result of the explosion, the well went completely out of control, causing vast amounts of oil to gush out into the sea for almost three months. Remote-controlled underwater robots were used in an attempt to trigger the shear rams on the BOP, but without success.

In its report, the committee describes in detail the technical failures and flawed decisions which, together, led to the disaster, and concludes that material improvements in the offshore oil development industry are required, not only in relation to technology, e.g. BOP construction, but also to management and safety systems and, above all, communication between the various service companies and the operator. The offshore drilling industry faces particular challenges and problems in deep waters, evident from the fact that it took the operator, BP, a considerable time to seal the gushing well on the sea floor. It was not until July 2010, three months after the blowout, that engineers managed to install a capping stack – a tall steel structure – on the BOP. The capping stack captured the oil flowing out of the BOP and funnelled it to a production rig.

The committee estimates the total economic costs of the disaster to be in the tens of billions of dollars. For example, after the disaster, a ban on commercial fishing and aquaculture was imposed across 200,000 square kilometres of the Gulf of Mexico in order to prevent fish and seafood contaminated with toxic hydrocarbons from getting to market. Although the ban has now been lifted across much of the Gulf of Mexico, some restrictions remain in force in severely affected areas such as the Mississippi Delta, where oyster farming is still prohibited. The tourism industry in Louisiana, Mississippi, Alabama and northwest Florida was also hit hard. The U.S. Travel Association estimates that the economic impact of the oil spill on tourism across the Gulf Coast over a three-year period could be as high as 23 billion US dollars. Fines totalling around 4 billion US dollars have already been imposed on BP, with a further 8 billion US dollars paid in compensation to settle tens of thousands of civil claims out of court. According to economists, the blowout at Deepwater Horizon has cost the company around 42 billion US dollars.

So far, no comprehensive scientific study has been carried out to determine which specific measures, and how many of them, have been implemented to make offshore oil development safer. However, various aspects have improved: manufacturers are now equipping their BOP systems with more reliable valves and shear rams, for example. The relevant US authority – the Bureau of Safety and Environmental Enforcement (BSEE) – has also strengthened the provisions on safety in offshore drilling operations, for example by reinforcing stop-work authority (SWA) rules. This empowers and requires any rig worker, irrespective of their position, to stop work and report an activity that is creating imminent risk. If a worker reports a violation, a more senior engineer must respond and take corrective action. Stop-work authority rules were already in existence before the Deepwater Horizon incident, but “red flags” from field-level personnel were often ignored.

In addition, companies are now required to establish, in writing, who has ultimate work authority on a rig for decision-making at any given time. This person must now be informed about every step in the work process. This was often lacking in the cooperation between the various service providers in the past: decisions were not always properly coordinated, or were taken by different people. As a result, mistakes sometimes went unnoticed – as in the case of Deepwater Horizon. Independent auditors now carry out checks on the rigs to ensure that the decision-making authority is clearly established, that the stop-work authority rules are being enforced, and that communication has improved. Are all these measures sufficient to avoid accidents in future? Only time will tell.

It is noteworthy that over the past three years, a new industry has developed, specializing in the production and deployment of capping stacks for the deepwater oil industry. Some of the companies involved were already well-established in the offshore industry, but others are new businesses. Furthermore, various oil companies have joined forces and set up their own projects to develop or supply capping stack technology and personnel for subsea incident response, not only in the Gulf of Mexico but worldwide. The companies have set up bases around the world, for example in Stavanger in Norway, Cape Town in South Africa, Angra dos Reis near Rio de Janeiro, and Singapore, with between six and 10 capping stacks kept on standby at each location, ready for deployment in an emergency. The aim is to reach a faulty well within hours or days. Special vessels are used to install the capping stack on the defective BOP. The oil can then be piped from the capping stack to a production rig in a controlled manner. In addition, various contingency plans are now in place as the basis for a managed response to disasters on the scale of Deepwater Horizon. These were developed, in some instances by several oil companies on a collaborative basis, at the insistence of the US government and are extremely detailed. Among other things, they envisage the use of semi-submersible rigs, which can be towed to the site of the incident and used to pump oil out of the capping stacks into tankers.

Biologists are still engaged in field studies to obtain a detailed picture of how the oil pollution has affected the water and coastlines, focusing on the status of diverse fauna, flora and habitats. These field studies are broken down into nine work packages which deal with the following: the water column and sediments in the Gulf, the shoreline, fish, marine mammals and sea turtles, nearshore habitats and communities, corals, crabs, birds, and submerged aquatic vegetation.

The extent to which biotic communities and habitats have been affected by the disaster is, to a large extent, still unclear, for it is difficult to determine whether certain types of damage to flora and fauna were indeed caused by contaminants in the oil or whether they perhaps predated the disaster. The problem is that the affected region extends across five US states and their respective coastlines and waters, covering a vast area. What’s more, the Gulf of Mexico has never previously been studied as intensively as it is today. For many geographical areas, or indeed for certain species of flora and fauna, no data predating the disaster are available. It is also unclear how many larger animals were killed by the disaster. According to surveys by the US authorities, up to November 2010, cleanup workers had collected around 6000 dead seabirds, 600 sea turtles and 100 marine mammals, such as seals and dolphins, which had washed up on the heavily impacted coasts of Louisiana and Alabama and had apparently been killed by the oil. However, according to some experts, the real death toll could be up to five times higher.

Furthermore, the number of dead animals washed up along the coasts has increased since the disaster. According to the National Wildlife Federation, there was an average of 24 dead sea turtle strandings annually from 2007 to 2009. This increased to 525 in 2011, 354 in 2012, and more than 400 in 2013. According to the National Oceanic and Atmospheric Administration (NOAA) in the US, the number of dead dolphins washing up on Gulf beaches has increased from an annual average of 63 between 2002 and 2009 to 229 in 2010, 335 in 2011, 158 in 2012, and more than 200 in 2013. It is too early to say for sure what has caused the higher death toll. Nor is it clear to what extent the oil that gushed from the deep well has damaged seabed habitats, but some researchers are convinced that the reproduction and growth of many benthic (bottom-dwelling) organisms will be disrupted for a long time to come. Other scientists take the view that the impacts are less severe than expected because large amounts of the oil were broken down by bacteria fairly quickly. Fears that the Gulf Stream might carry the oil from the Gulf of Mexico along the Florida coast into the Atlantic and perhaps even to Europe soon proved to be unfounded; the oil pollution remained confined to the Gulf of Mexico. ![]()

fig. 1.35 > After the explosion on 20 April 2010, the Deepwater Horizon drilling rig burned for several days. Attempts to extinguish the fire with water cannons failed. Finally, the rig capsized and sank into the waters of the Gulf of Mexico. © Gerald Herbert/picture alliance/AP Images

fig. 1.35 > After the explosion on 20 April 2010, the Deepwater Horizon drilling rig burned for several days. Attempts to extinguish the fire with water cannons failed. Finally, the rig capsized and sank into the waters of the Gulf of Mexico. © Gerald Herbert/picture alliance/AP Images

fig. 1.36 > The oil slick reached the Louisiana shoreline.

© picture alliance/dpa Erik S. Lesser

fig. 1.36 > The oil slick reached the Louisiana shoreline.

© picture alliance/dpa Erik S. Lesser

fig. 1.37 > Barriers were erected in a futile attempt to protect Dauphin Island. © Brian Snyder/Reuters

fig. 1.37 > Barriers were erected in a futile attempt to protect Dauphin Island. © Brian Snyder/Reuters

fig. 1.38 > Barges lined up to seal off Lake Pontchartrain near New Orleans. © Lee Celano/Reuters

fig. 1.38 > Barges lined up to seal off Lake Pontchartrain near New Orleans. © Lee Celano/Reuters

fig. 1.39 > Wind, wave action and currents caused the oil to spread. © Dave Martin/picture alliance/AP Photo

fig. 1.39 > Wind, wave action and currents caused the oil to spread. © Dave Martin/picture alliance/AP Photo